MENU

DK | DKK

DK | DKK

No results found

Search Suggestions

Regulatory info

Regarding suitability of Eppendorf bioprocess equipment for the production of food, please reach out to your Eppendorf sales representative.

Bioprocessing for Modern Food

You lead the way to new ways of food bioprocessing. At Eppendorf, we are dedicated to paving your path. The food industry is facing a revolutionary transformation. Emerging production technologies offer more plant-based and animal-free food alternatives that promise to reduce the issues related to livestock – from deforestation to microbial antibiotic resistances, and concerns regarding poor animal welfare.

Whether it is the creation of cultured meat from stem cells, or the production of modern food using fermentation, come and talk to us, we are all ears.

Whether it is the creation of cultured meat from stem cells, or the production of modern food using fermentation, come and talk to us, we are all ears.

Read more

Read less

Discover the world of lab grown meat and how to produce it in bioreactors in our ebook "Bench to burger: The future of food from the lab".

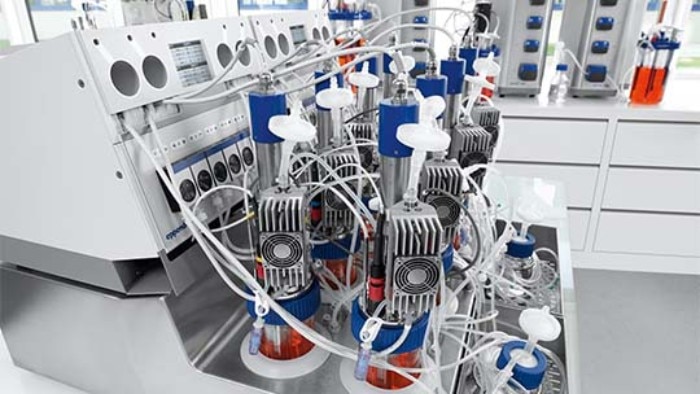

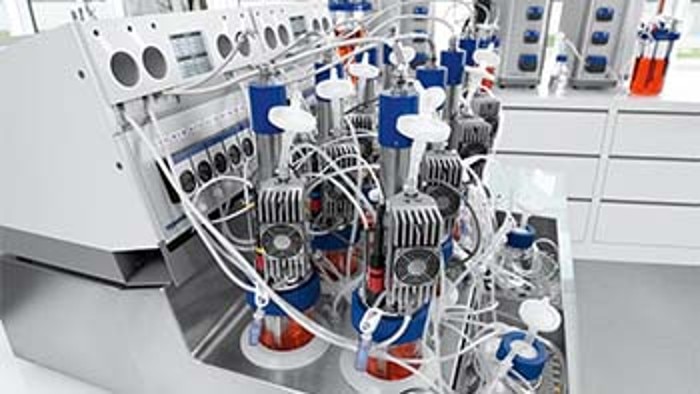

Eppendorf solutions to produce food in the lab

Bioprocessing for modern food is unique to every business and might be based on stem cells, other eukaryotic cell types, or bacteria. At Eppendorf, we pay attention to your specific challenge and we focus on empowering your business with tailored bioprocess solutions.

- Application flexibility: Cultivation of stem cells, mammalian cell lines, and microorganisms

- Scalability: Working volumes from 65 mL to 2,400 L

- Process optimization: Innovative hardware and software solutions to optimize process control, automate tasks, and harness the power of your data

- Time-saving and risk mitigation: BioBLU® Single-Use Bioreactors can be used as an option with most Eppendorf bioprocess systems to reduce the contamination risk and save setup time

Read more

Read less

Customer stories

The real experts are our customers. Meet some of them and find out what their work is all about.

Read more

Read less